蒯女士

4小时前在线

已认证

- 职位介绍

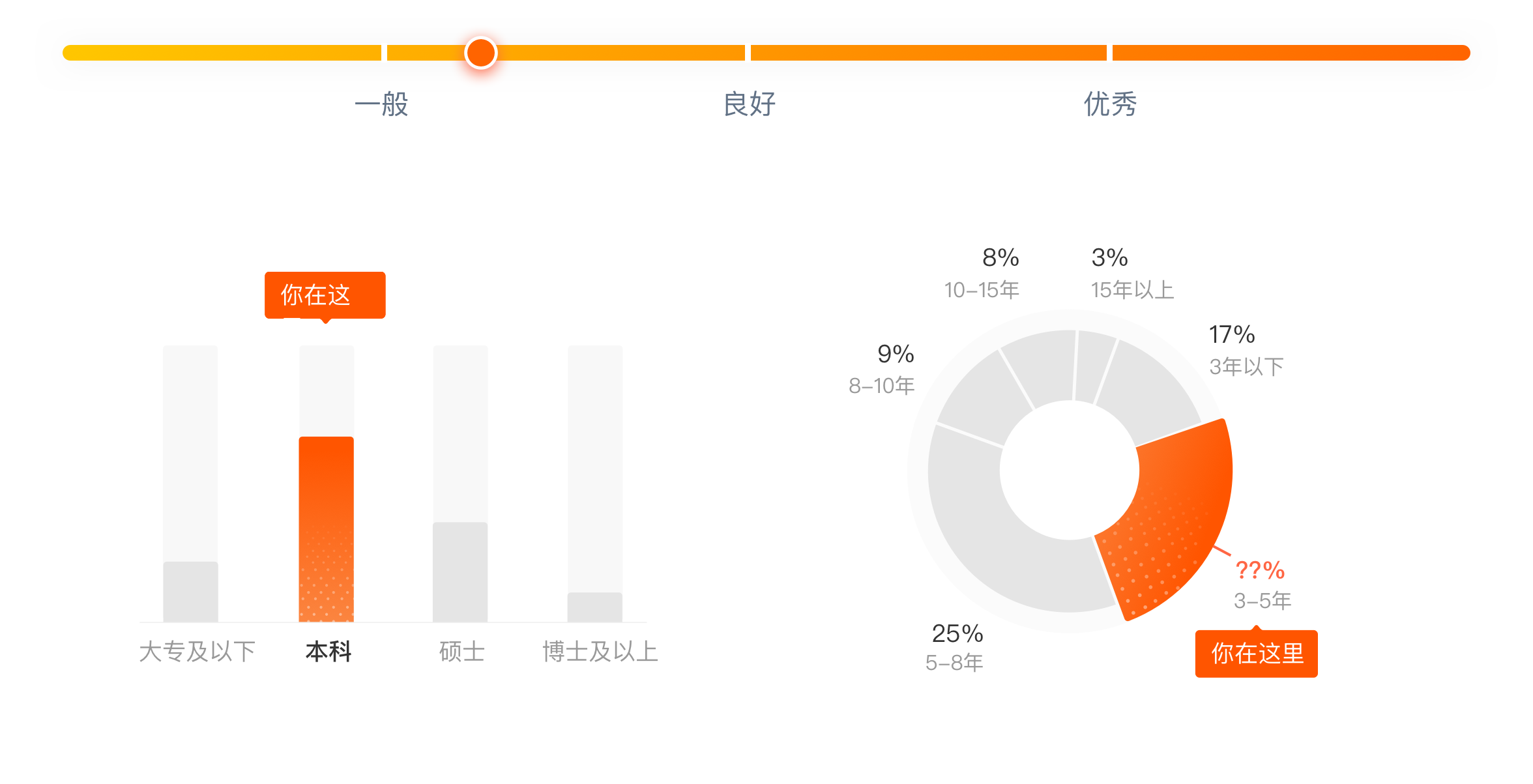

- 1. New supplier selection 1) Understand business requirement from technical point view including transferring it into detailed technical requirement, selecting suitable drawings for quotation and drafting the capability matrix template for benchmarking. 2) Work with sourcing team to pre-visit suppliers and can identify suitable supplier from technical point view. 3) Join/Lead audit team to follow the audit process to assess the supplier according to the defined audit agenda. 4) Complete the formal audit report with updated on the corrective action until closure, and archive the audit report. 2. New production development projects and cost saving projects 1) Be able to review the drawing in English, understand notes, GD&T for machining part, IPC for EE parts, and other technical data, and identify the critical to Quality (CTQ) dimensions for DFM. 2) Contact and address with engineering team for any issues in drawings / technical specification. 3) Dig out the risk on part's manufacturing, and work with supplier how to fix it before manufacturing. 4) Work with suppliers for drawing review and follow up the questions/issues. 5) Understand the template of quality plan-QP(PPAP) and can instruct/coach supplier to complete QP(PPAP). 6) Be able to review supplier QP to point out the issues and follow up the correction. 7) Work with inspection team to review suppliers' inspection methods and ensure it's aligned. 8) Be able to identify critical manufacture process and on-site monitor/evaluate the process according to the WI or QP. 9) Approve sample according to QP and can identify any issue in sample failure and solve it accordingly. 10)Monitor the sample qualification process to ensure the spec was updated timely. 11)Monitor supplier's new product FAI pass rate and drive supplier to improve if the pass rate is below target. 3. Mass production quality management 1) Understand the key quality issues of assigned commodities/suppliers and identify solutions to meet DPPM target through quality tools. 2) Be able to understand the quality issue in production line and judge whether it's suppliers' fault by evidence. 3) Promptly follow up the quality notification(QN) and work with suppliers to identify the root cause and follow up the corrective actions. 4) Assure supplier’s corrective and preventive action plans are developed and executed in compliance with Nordson expectations. Report on the status of corrective actions, as required, to manufacturing, business group and executive management. 5) Conduct process audit if necessary when the SCAR(8D) is issued. 4. Supplier Development 1) Define goal for key supplier based on history performance and monitoring the trend. 2) Regular communication of the performance with key suppliers’ top management team. 3) Set up face to face Quality Review Meeting with supplier management team when necessary. 4) Understand the assign commodity strategy. 5) Monitor and analyze the key supplier performance and key issues at all factories, pay attention to the common issues or improvement opportunity for overall commodity. 6) Initiate Process Audit on supplier for existing issues or potential risks, close the corrective actions within due date. 7) Understand/Develop the key supplier capability matrix, and understand the key supplier's development plan, help supplier to improve gap or continue develop strength. 8) Understand the commodity market benchmark and the gap between supplier base and market. 5. Supplier Risk Management 1) Follow up through direct supplier on 2nd tier supplier quality issues. 2) Understand the process of the key 2nd tier supplier and work with the direct supplier to manage the risk of key 2nd tier suppliers. 3) Map the key and risky process at supplier and 2nd tier supplier for existing parts. 4) Recognize the potential risky process at supplier and 2nd tier supplier for NPD or Cost Saving projects. 5) Good communication with sourcing on the risks captured for existing parts or NPD/Saving project parts to help in project allocation. Face to face Quality Review Meeting with supplier management team. Education and Experience Requirements 1. Bachelor degree education or above, major in Industry of Electrical Products/ Home appliance products/ Automation equipment. 2. 5 years of relevant experience. 3. Expert in the Root Cause Analysis process and help supplier to follow 5 Why and PDCA to solve problems. 4. Proactively use Lean and Six Sigma tools to audit the supplier process to help avoid issues or achieve process improvement and value enhancement. 5. Good communication skills with internal and external. Travel Required: Domestic 30%

- 其他信息

- 语言要求:英语、普通话

- 所属部门:Production Support

公司简介

诺信公司提供精密喷涂技术及解决方案帮助全世界的客户取得业务成功。我们设计及制造与众不同的产品,用于胶粘剂、涂层、密封剂、生物材料、聚合物、塑料及其他材料的精密喷涂;用于流体管理;测试和检查以及紫外线固化和等离子表面处理。我们通过专业的喷涂技术和全球直接销售和服务来为我们的产品提供支持,为快消、耐用品和技术终端市场的广大消费者提供服务。诺信公司成立于 1954 年,总部位于美国俄亥俄州韦斯特莱克,目前在全球超过30个国家/地区设有运营机构和支持办事处。

查看全部

猎聘温馨提示:

- 1. 如您发现平台内招聘方存在以下违规行为的,请立即举报

-

- a. 扣押您的身份证件或者其他证件;

- b. 要求您提供担保人、担保金或者以其他名义向您收取财物( 如培训费、体检费、资料费、置装费、押金等);

- c. 强迫您入股或者向您集资;

- d. 以招聘名义牟取不正当利益;

- e. 发布虚假招聘广告信息;

- f. 存在其他损害您的合法权益的行为。

- 2. 如您应聘的岗位属于涉外劳务合作/海外岗位的,请务必核实招聘方对外劳务合作资质取得情况,同时注意自身资金安全,防范招聘欺诈。

- 了解更多安全防范知识>

猜你喜欢

项女士

Head of Talent Acquisition

蒋女士

资深招聘

孟女士

人事经理

陶女士

Sr. Recruiter

李先生

人事主管hrbp

王女士

Recruiter

陈女士

Talent Acquisition Lead, China

1

2

3

4